An aluminum boat is a clean, effective way to enjoy the open

water. But the quality of your aluminum is obvious to anyone looking at

it—especially if there’s an issue. That’s why you’ll have to know how to seal

an aluminum boat by using the right techniques and a few helpful products along

the way.

Inspection

The first step in ensuring you seal an aluminum boat properly is to be sure you understand the full context for

what your boat needs. Aluminum is constructed with seams and rivets, which may

be prone to leaking if they get loose. If you’re aware of a leak but aren’t

sure about its source, get the boat dry and watch for any leaks, paying special

attention to the areas of seams and rivets. These are your primary suspects for

leaks that you may need to seal.

That doesn’t mean, however, that every leak will start at

these sources. Make sure to give your entire boat a look-over and double-check

before proceeding.

Prep The Area

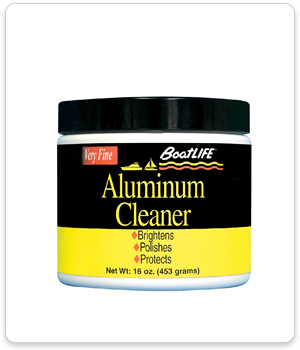

What happens when you’ve identified a leak? It’s time to

prepare the area. Use a dedicated Aluminum Boat Cleaner

to ensure that you get the highest quality of clean while also protecting the

metal itself. Give the area enough time to dry out so that you can work with a

smooth, clean surface without any interference from lingering water.

Sealing Your Boat

With the aluminum adequately prepared, you’re ready to move

on to the next step: sealing an aluminum boat. Here’s what you’ll need to know:

- Choose the

right sealant for your boat material. When working directly with aluminum,

you’ll want a sealant specifically designed to adhere to metal. At the very

least, the label should let you know that the sealant adheres to metals. For

example, a cartridge of Life-Calk

will seal to metals, and the acid-free formula of Silicone

Rubber Sealant won’t corrode metal. Stick with the Silicone Rubber

Sealant to ensure that your metal is well protected. After all, you want to get

the full life from your boat.  Apply the

Apply the

sealant, and don’t be afraid to be generous. It’s better to over-seal than under-seal,

as you can always go back over the area you’ve sealed and scrape off excess

sealant. If you under-seal, however, you may find yourself having to start all

over. In some cases, that may mean you have to remove the old sealant, although

some products will be able to adhere to themselves. Make sure you always read

the label to understand which product you’re working with. A few seconds of

reading the label could spare you hours of manual labor.

Follow the directions of your boat sealant to ensure a

proper cure. This often requires keeping the boat in a stable place to cure

overnight. After that, you should inspect the seal and test to see if it’s

waterproof.

Need more aluminum boat care products to help

sustain your boating lifestyle? Keep browsing everything available here at

BoatLIFE.