Even when you inspect your hull regularly, there’s one area of your boat that can often get overlooked: the transom. New boat owners aren’t even aware that the surface of their boat’s stern even has its own name. But if you want your boat to look its best, checking and repairing the transom is essential. But that still leaves one question: how do you check and repair transom issues on your boat? Here’s a simple guide to help.

Add a Transom Inspection to Your Boat Maintenance Routine

When you look over your boat’s hull for problems, never skip the transom. Even if the thought of trying to fix a transom issue fills you with dread, you’ll always do better if you spot an issue sooner rather than later. Usually, a problem with the boat transom does mean you’re in for either a costly or a labor-intensive repair—or both.

For example, repairing an outboard on your boat transom can mean removing the transom top, removing any associated fixtures, digging out bad and rotted wood, letting the interior dry, treating the area, and re-assembling. If it sounds like a lot of work, that’s because it is.

Because problems like rot frequently plague boat transoms, you’re going to need to regularly inspect the transom for rot problems specifically. The good news is that there are dedicated products to help treat this kind of boat rot.

Git-Rot: An Alternative to Hard Work & Expensive Repairs

What if there were an easier way to repair rotted wood out of a boat transom without the extensive labor and expenses?

What if there were an easier way to repair rotted wood out of a boat transom without the extensive labor and expenses?

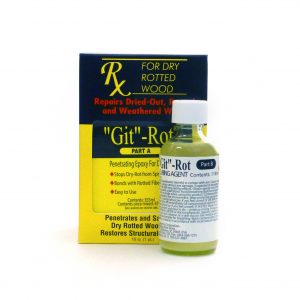

There is. Git-Rot is a two-part liquid epoxy designed to fill and restore wood back to its original strength by treating the rot at its most problematic points. By injecting Git-Rot directly into the wood, you bypass all the disassembling and reassembling of transom repair and treat the problem at its source.

This isn’t to say that Git-Rot will require absolutely no work at all. There are a few best practices to treat your transom wood:

-

- Wait for the ideal temperature—between 50 and 70 degrees Fahrenheit. At about 70 degrees, the applied Git-Rot will solidify overnight, boosting the wood’s strength.

- Inject the Git-Rot into the wood’s end grain whenever possible. Think of Git-Rot like blood moving through capillaries: in order to reach the most wood, it has to sink in and move around with the wood’s fibers. By seeking out end grain, you have more direct access to the wood’s interior, which boosts the performance of Git-Rot.

- Inject into dry wood. While Git-Rot will eventually cure even in damp wood, it works much better in dry wood, as the epoxy solution will move around more freely and better saturate the wood.

Final Thoughts

The transom on your boat is like the caboose on a train: it’s all anyone sees after you’ve passed. Regularly inspect this area, apply Git-Rot when needed, and you’ll go far in extending the life and quality of your boat.